Milestones

Pioneers & "Firsts"

Our journey is now more than five decades. The journey has been at times easy and at times strewn with impediments. But the fortitude to deliver in the most adverse conditions, the team spirit and respect for all stakeholders and the ability to dream and the courage to realize them has made TRF a trusted and a differentiated enterprise in the area of integrated material handling solutions.

Listed below are some historical moments in the TRF Ltd voyage through these last over 60 years

- NTPC Vindyachal and IFFCO Paradip projects were contractually closed.

- Successfully completed, commissioned and handed over the NTPC Singrauli site.

- Entire 71 Km of conveyor belt laying at NMDC, Nagarnar.

- Major equipments manufactured viz., Double Roll Crusher, Sleeve Loading System, Mill Hood Platform Structure and Entry Scrap Disposal System for TSL, Kalinganagar.

- Installation of Plate Cutting Machine at the Jamshedpur plant in Bay # 2.

- Completed several projects: BHEL, Meja, Wanakbori and two out of the seven circuits at Nagarnar.

- Commercial operation of the 2nd unit of the 660 MW commenced through the Coal handling system provided by TRF in NPGC-Nabinagar.

- Noteworthy projects executed for Tata Steel were erection & commissioning of the Wagon Loader at West Bokaro, Booster Pump house and pipeline work for in-pit slime dam at Joda, refurbishment of Wagon Tippler for HMC Coke circuit.

- Mr. T V Narendran appointed as Chairman

- Mr. Alok Krishna appointed as Managing Director

- Mr Rajesh Ranjan Jha appointed as Chairman

- Mr. Sumit Shubhadarshan appointed as Managing Director

- Launch of Life Cycle Services

- Mr Sanjay Rajoria appointed as MD, TRF

- TRF develops Sizer for Coal Crushing

- Innovation In Travelling Plough Feeder Ensures Efficient Coke Handling

- HRIL & TRF add flip flow screens to product basket

- Designed and developed smooth double roll crusher

- Mr. P S Reddy appointed Managing Director on S L Deoras’ completion of tenure.

- Promoted eco-friendly and safer material handling equipment by demonstrating capability to design and manufacture product powered by solar energy and monitored from distance.

- Mr. PS Reddy appointed as Deputy Managing Director on May 29, 2015.

- Tied up with TIDFORE and CEEEC – both Chinese companies for stockyard equipment and Equipment for thermal power plants.

- TRF launched new vision in June 2014 to achieve technological leadership.

March 03, 2013

Mr. Cyrus P Mistry, Chairman, Tata Sons and Mr. Ratan N Tata, Chairman, Emeritus, visited TRF on Founder’s Day on the occasion of Golden Jubilee celebration and paid floral tribute to the Founder.February 23, 2012

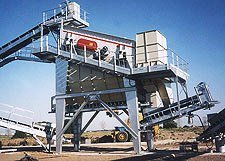

Agreement signing between TRF Ltd and Schade, Germany. Standing from left to right: Mr. Michael Wieland – General Manager-Sales, Scahde, Mr. Biswajit Shaw – Head Business Development, TRF, Mr. Karl-Heinz Fiegenbaum- Managing Director, Schade and Mr. Matthew Jones, Sr Sales Manager-Schade in Germany. TRF and Schade, Germany join forces to offer higher capacity yard equipment in India. Jamshedpur February 23, 2012 TRF Limited, a Tata Enterprise and Schade Lagertechnik GmbH have signed a strategic co-operation agreement to give TRF the exclusive right to manufacture and market Schade’s yard equipment in India. This agreement aims to fulfil the need for higher capacity Stackers, Portal Scraper Reclaimers, Circular Storage Systems as well as Wagon Tipplers, to meet the ambitious growth plans made by the Indian infrastructure industries such as power, steel, ports, cement, mining, etc. Under this agreement, Schade, Germany will provide TRF the necessary know-how, assistance and key components for making higher capacity yard equipment and thus ensure the success High Energy Screen |  Quad V Screen |  Jaw Crusher |  Mobile Crusher |

- Bay-7 was erected to add 5760 square meters of covered space.

- In April, 2010, TRF took another step forward in the direction of globalisation by acquiring UK Based Hewitt Robins International Ltd (HRIL),

- bulk material handling equipment manufacturing company. With this acquisition, HRIL, bulk material handling equipment manufacturing company.

- With this Acquisition, HRIL became a 100% subsidiary of TRF Ltd.

- Installed Asia’s first & biggest Radical Stacker Reclaimer (1800 TPH) in technical association with Schade, Germany.

- Acquired 100% equity shares of York Transport &DLT.

- Rain water harvesting facility set up to address the need of potable water in areas adjoining TRF Colony and TRF Works.

2008-09

1. On 7th July 2009, TRF Ltd signed an agreement to acquire 51% of equity shares at a consideration of US$ 8.67 mil of Dutch Lanka Trailer Manufacturers Limited (DLT).

2.TRF announces the issue of Bonus Shares in the ratio of 1:1 (i.e. one share for every one share held by the existing shareholders of the Company).

TRF’s Maintenance Department managed to successfully recondition, erect and commission a Skoda Horizontal Boring Machine Model WD-1604, purchased from M/s Telco Ltd.

In the year 2000-01, the company signed a Co-operation Agreement with M/S Landers Maschinefabrik, Germany, for the manufacture and sale of grab buckets and for the conversion of shipboard cranes.

2007-08

TRF signs an agreement to form a joint venture, ‘Adithya Automotive Applications Private Limited’ with Tata Capital Ltd and Jasper Industries Pvt Ltd to produce automotive applications.

TRF announces the issue of Bonus Shares in the ratio of 1:1 (i.e. one share for every one share held by the existing shareholders of the Company).

Acquisition of 51% equity shares York TEA, Singapore, a wholly owned subsidiary of Baker Technology Ltd on October 5, 2007, symbolized a new beginning for TRF Ltd. It was a major step towards globalization.

TRF Ltd scored an impressive 487 points (out of maximum of a 1000) at the last TBEM assessment.

Several projects were successfully completed:

1. Lignite & Lime Handling Plant at GMDC, Akrimota.

2. Coal Handling Plant at Parichha.

3. Raw Material Handling System – III, for Bhushan Steel Limited.

4. Supply of Stacker overseas; South Africa, for the first time.

TRF bagged its first direct export order from Doosan Heavy Industries & Construction, South Korea for supply of a reversible stacker reclaimer for their project in Cirebon in Indonesia.

2005-06

Winning the SERIOUS ADOPTION OF TBEM AWARD 2005

TRF participating in the Moral Re-Armament Training & Workshops

TRF participating in the Moral Re-Armament Training & Workshops

TRF was awarded the SERIOUS ADOPTION OF TBEM AWARD 2005, based on their performance in the TBEM External Assessment in 2005.

TRF participating in the Moral Re-Armament Training & Workshops

TRF participating in the Moral Re-Armament Training & Workshops

TRF has diligently participated in the Moral Re-Armament training and workshops on a regular basis.

2004-05

Special Purpose Facing Machine

The following years; 2004-05, was a statement of the authenticity of the technology furnished by TRF Ltd mini blast furnaces. Two blast furnaces, of 2.5 cubic m capacity and the other of 250 cubic m, engineered by the company went on stream.

In the same year, on March 23rd, in a meeting of the Board of Directors, the Whistle Blower Policy was adopted for TRF Ltd.

TRF designed, developed and manufactured a “Special Purpose Facing Machine” in-house to undertake the facing, drilling and boring operations for components of screens, cutting down on costing.

2003-04

Level Luffing Cranes at Tuticorin Port

TRF, always one to create benchmarks, engineered and manufactured three Level Luffing Grab Cranes, the fastest in the country, which were dedicated to the Tuticorin Port.

TRF Ltd continued to grow by leaps and bounds! In collaboration with SMS Demag, the company in 2003-04, in a bid to explore new avenues, began providing ‘design and engineering’ services for mini blast furnaces, while also adopting the following vision, quality policy and theme:

Vision

The company shall be- “A premier provider of engineering products, systems, services and solutions, with a global presence and inspired team creating sustained value for all its stakeholders”.

Quality Policy

TRF Ltd shall provide engineering Products, systems, Services and Solutions that consistently meet its customers quality requirements in terms of specifications, performance and delivery, and shall continually improve the effectiveness of its Quality Management System……..

Company Theme [R-I-S-E]

Raise Stakeholders’ Value

Inculcate an inspirational environment through learning and change

Secure premier leadership position for Company’s Engineering Products, Systems, Services and Solutions

Establish global presence……………..

For the first time, the Port & Yard Equipment Division- its Quality Management System was certified under ISO 9001:2000 standards.

2002-03

Hydraulic Plough Feeder for Reclaiming Coal at 1200 TPH

TRF Manufactured a Hydraulic Plough Feeder for reclaiming coal at 1200 TPH for the NTPC Talcher Project

2001-02

SCP Technology Adopted at Tisco’s Battery No. 9

SCP Technology Adopted at Tisco’s Battery No. 9

TRF supplied the Stamp Charging Pushing (SCP) Machine and the Coke Gas Transfer Car (CGT) to Tata Steel, in collaboration with Koch Tranporttechnik, GmbH, Germany.

For the first time, the company, in compliance with the Accounting Standard on Segment Reporting (AS-17) and Clause 41 of the Listing Agreement with the Stock Exchanges, disclosed the segment results of the four divisions for the second quarter of the financial year 2001-02.

8 Level Luffing Cranes Supplied by TRF to Visakhapatnam Port

8 Level Luffing Cranes Supplied by TRF to Visakhapatnam Port

TRF designed and supplied 15-tonne capacity Electrical Level Luffing cranes, first of their kind in India to Visakhapatnam Port. These continuous duty cranes conform to BS 2573 Standard Specifications and have converter drive as a special feature.

Moreover, the company’s EPC/ EPCM division was also accorded a Certificate of Registration under ISO 9001:1994 for “engineering, procurement and construction, contracting and project related management services”.

The quality system of Bulk material Handling Equipment division was re-certified to be in accordance with the ISO 9001 standards.

Inauguration of the JRD Tata Learning Center

Inauguration of the JRD Tata Learning Center

Inauguration of the JRD Tata Learning Center

The JRD Tata Learning Center was inaugurated on the TRF premises, thus addressing the long- standing need of an essential facility required for imparting knowledge to the TRF employees.

2000-01

Skoda Horizontal Boring Machine Inaugurated

Under the Year 2000 Compliance, the hardware, software and embedded systems pertaining to the different divisions of the company rolled over smoothly on the night of December 31, 1999 without any disruptions in the operations.

TRF signed the BE-BP Agreement and the Tata Code of Conduct with Tata Sons.

TRF’s Maintenance Department managed to successfully recondition, erect and commission a Skoda Horizontal Boring Machine Model WD-1604, purchased from M/s Telco Ltd.

In the year 2000-01, the company signed a Co-operation Agreement with M/S Landers Maschinefabrik, Germany, for the manufacture and sale of grab buckets and for the conversion of shipboard cranes.

1983-84

The Company’s application for patenting of an improved wagon clamping device used in, wagon tipplers was registered

1987-88

The Company; also introduced the ‘Stamp Charging Technology’ in association with SAARBERG Inter-plan, West Germany, for improving the quality of the coke oven batteries used in steel plants.

TRF, through these years, continued to grow and enhance its expertise. The Company started manufacturing underground mining vehicles; load haul dumpers and side discharge loaders. An imported Gantry — Plano Miller – with a versatile range was also commissioned.

Stamp Charging Technology

Side Discharge Loader

1987-88

The Company; also introduced the ‘Stamp Charging Technology’ in association with SAARBERG Inter-plan, West Germany, for improving the quality of the coke oven batteries used in steel plants.

TRF, through these years, continued to grow and enhance its expertise. The Company started manufacturing underground mining vehicles; load haul dumpers and side discharge loaders. An imported Gantry — Plano Miller – with a versatile range was also commissioned.

Stamp Charging Technology

Side Discharge Loader

1975-76

TRF Ltd bagged the prestigious order from the Haryana State Electricity Board for a coal handling plant for their new therrnal power station at Panipat.

1976-77

- The heavy fabrication Bay was completed in record time of five months.

- A metallurgical laboratory and radiography facilities were also installed during the same year.

- The Company secured a major order for supply of raw material blending systems, consisting of radial stackers and reclaimers. This concept was one of the “firsts” in India- enhancing the operations and efficiencies of cement plants.

- The Government of India, Department of Science and Technology, recognized the Research and Development Department of TRF Ltd for a period of three years, valid till March 31, 1979.

1962-63

TRF Ltd was incorporated on November 20, 1962, as Tata Robins Fraser Ltd. It was promoted by Tata Steel and the Associated Cement Companies Ltd (ACC), in financial and technical collaboration with Hewitt-Robins Inc. (HR) of USA and the General Electric Company Ltd (GEC)— Fraser & Chalmers Division of UK.1964-65

TRF Nagar was planned when the Company acquired 30.44 acres of land from Tata Steel on lease. The colony would comprise 136 housing units, necessary roads and civic amenities.1965-66

- Production commenced in April 1965.

- Sales offices opened in Mumbai and Kolkata.